14 Ways to Make Colloidal Silver

- Peter L. Reynolds, Ph.D.

- Apr 27, 2015

- 3 min read

Actually, we've identified at least 14 different methods on how to make colloidal silver. (Probably, within each method, there's a vast range of unique twists and turns.) in 5 different Groups. These Groups include: (1)Grind; (2)Wave; (3)Liquid; (4)Chemical; and (5)Electrical. The following table portrays the various methods within the five groups. It also identifies the earliest recorded date when each method was employed.

As you can see, there were a wide variety of methods used in making colloidal silver, stretching clear back to the 1860's.

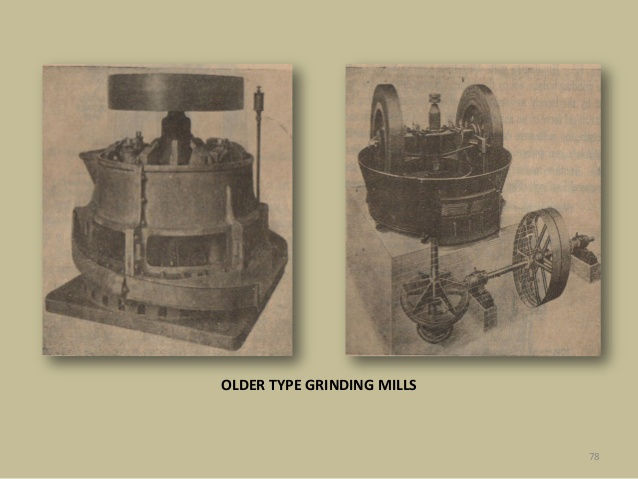

GRIND GROUP - All of the Grind Group methods have pretty much the same manufacturing problems. The first problem is grinding the silver down to the sizes required by a colloid. It is very difficult to grind anything down to the 5nm to 100nm colloidal range, consistently (An "nm" = nanometer = .001 micron = one thousandth of a micron = one thousandth of one millionth of a meter. You may want to look at, What Does Colloidal Mean? Part 1, if you haven't, already.). Such a powder would be far finer than any wheat flour.

The second problem is attempting to establish a like-electrical-charge on all the particles. Without the uniform charge, the particles tend to eventually settle to the bottom of the container. Thus, the Grind Group methods of manufacturing colloidal silver are always having a hard time producing a stable, true colloid.

Some of the bad press concerning the non-reliability of colloidal silver and the potential hazard of silver discoloration, argyria, and heavy metal deposition came from Grind Group silver colloids. In truth, it was the high concentrations of the non-colloidal portion of the suspension which caused the discoloration problem. The average particle size (mass) of the silver particles from grinding is just too large for whatever uniform charge the particles may contain. This, coupled with the difficulty of producing a uniform charge in the first place, dooms this manufacturing group to producing a low grade colloidal silver.

WAVE GROUP - The Wave Group of methods showed some real promise when manufacturers initially started looking at using this group of methods. Often, we think using ultrasonic bombardment must have been something from the end of the 20th Century. Instead, ultrasonic bombardment was first used to make colloidal silver in 1921. This manufacturing group worked quite well at producing a consistent colloidal particle size. However, it failed to provide a way for establishing a uniform electrical charge on all the particles. As a result, the stability issues were not solved by this manufacturing group.

LIQUID GROUP - The Liquid Group of methods also ran into the stabilization problem of keeping the silver particles suspended. Again, because such metal sols are hydrophobic (water-hating), the water offers no real help in keeping the particles in suspension. On the other hand, sometimes these methods provide particles that are too small, a molecular suspension (smaller than 5nm). Typically, such molecular silver is often quite toxic. The Liquid Group of methods doesn't provide the mechanism to achieve stability with the correct colloidal particle sizes.

CHEMICAL GROUP - The chemical action method was probably the most often described before 1938, and, consequently, was the most often referred to in post-'38 literature. However, one of the real problems with the chemical action method is getting rid of the chemicals, once the colloidal silver is made. Second, this group of methods often produce mostly molecular suspensions, i.e., a majority of silver particles smaller than the 5nm lower colloidal limit. A third problem is establishing the uniform charge on the particles to keep the particles suspended. As a result, a fairly low grade colloid of silver is typically made using the chemical action method.

ELECTRICAL GROUP - Finally, there is the Electrical Group of methods. The challenges in this group have to do with the specifics. How many amperes of current must there be? What must the voltage be? How do you get demineralized/distilled water to be a semiconductor? What should the electrical elements look like? What should they be made out of? How do you position these elements? The list goes on and on.

It's not a question of whether this group of methods makes the best colloidal silver. This manufacturing group does. However, finding the exact settings in combination with all the other factors has always been very elusive. Today, although most manufacturers of high quality colloidal silver use some method that falls within the Electrical Group, the variety of silver colloids with their different attributes clearly indicates how elusive those precise settings and factors really are.

Coming next, Whats Wrong With Homemade Colloidal Silver and Colorless Colloidal Silver?

Ready to buy the best colloidal silver in the market? Click here.

Comments